As a highly thermal-conductive filler and radiating filler material

In recent years, semiconductor devices and electronic devices for LEDs are getting smaller and smaller, moving toward high-density integration. As a result, thermal management will become a problem and highly thermal-conductive filler will be needed in the fields of thermal grease, thermal sheets and more. Our product has highly thermal-conductive and radiating performance, and is a very stable, safe material. We have an assortment of high-performance spherical SiC products, and we’ll continue pursuing the unlimited possibility of SiC.

Characteristics of SIC

| Thermal radiation rate(ε) | 0.9 |

| Thermal conductivity (W/m·K) | 270 |

| The rate of thermal expansion(10-6/ °C) 20 °C | 4.5 |

| luminous reflectance (240nm to 2,600nm) |

18 % |

| Hardness | New Mohs hardness: 13 (diamond new Mohs hardness: 15) |

| True specific gravity | 3.15 to 3.20 g/cm3 |

| Corrosion resistance | Chemically stable, and corrosion resistance to acid and alkali. |

![]() Thermal radiation rate (reference value)

Thermal radiation rate (reference value)

| Name | Thermal radiation rate | Name | Thermal radiation rate |

| Silicon carbide | 0.9 | Aluminum oxide | 0.4 |

| Aluminum | 0.2 | Copper | 0.1 |

| Iron | 0.3 | Zirconia oxide | 0.7 |

| Zinc oxide | 0.1 | Magnesium oxide | 0.4 |

![]() Thermal conductivity of silicon carbide and other ceramics & metals (W/(m·k))

Thermal conductivity of silicon carbide and other ceramics & metals (W/(m·k))

Note: numbers in parentheses are thermal conductivity values.

See thermal conductivity values, document values.

See thermal conductivity values, document values.

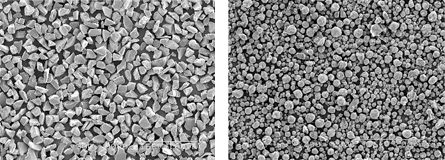

- SiC fine powder product (SHINANO-RUNDUM CP/GP)

- Spherical SiC product (SSC series)

- High thermal conductive product (X-12)

* More details about the high thermal conductive products,

please feel free to contact us.

please feel free to contact us.