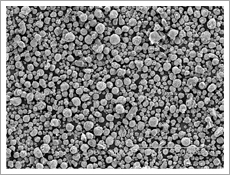

Spherical SiC

Developed as a heat radiating material for higher thermal conductive performance in terms of high filling and fluidity.

Applications

- Radiating filler material

Focusing on high thermal conductivity of 270 W/m·K to enhance bulk crystal and radiation performance, spherical SiC has high expectations for use in heat dissipation sheets, thermal grease, heat dissipation tape and thermal compounds. - Filling material with abrasion resistance and high thermal conductivity

Used as a composite material with heat resistance and high thermal conductivity, spherical SiC has excellent characteristics of repletion because of its round shape. - Ceramic sintered material

Silicon Carbide has heat resistance, corrosion resistance and is very firm. In addition, spherical SiC has excellent moldability characteristics including fluidity and uniform particle size distribution, and is thus being looked at for a wide range of raw materials. - Coating and composite plating material

Spherical SiC is used as a coating and composite plating material to enhance heat-resistance, abrasion resistance, high strength and sliding properties of automobile and aircraft components.

Product types and properties (standard values)

| Product type | Average particle size (µm) | Specific surface area (m2/g) | Circular degree | SiC (%) | F·C (%) | T·Fe (%) |

|---|---|---|---|---|---|---|

| SSC-A40 | 34.0~42.0 | 0.2~0.6 | 0.95< | 98.0< | <1.5 | <0.5 |

| SSC-A30 | 24.0~32.0 | 0.2~0.4 | 0.95< | 98.0< | <1.5 | <0.5 |

| SSC-A15 | 15.0~21.0 | 0.3~0.5 | 0.95< | 98.0< | <1.5 | <0.5 |

| SSC-A05 | 3.5~5.5 | 0.5~2.5 | 0.95< | 98.0< | <0.3 | <0.1 |

| SSC-A01 | 0.8~1.6 | 2.0~6.0 | 0.95< | 98.0< | <0.3 | <0.1 |